powermill 2022 что нового

Expert 3- and 5-axis CAM

Features included in Fusion 360 with PowerMill® enable easier 3- and 5-axis programming, simulation, and verification, so manufacturers can get more from their subtractive, additive, and hybrid machines.

High-speed machining

Expert performance

Rapid calculation of toolpaths for large or complex parts. Machine surfaces, solids, or meshes. (video: 2:48 min.)

High-speed roughing

Cut parts faster with high-efficiency roughing. Prolong tool life and reduce maintenance costs. (video: 3:15 min.)

Comprehensive finishing

Access a vast library of toolpaths. Improve surface finish, while minimizing manual polishing. (video: 3:02 min.)

Toolpath optimization

Make global or localized edits to your toolpaths without the need for lengthy recalculations. (video: 2:44 min.)

Hybrid manufacturing

ULTIMATE (Subscriber benefit)

Create, control, and simulate deposition strategies for driving high-rate additive processes. (video: 2:40 min.)

Surface probing

ULTIMATE (Subscriber benefit)

Create probing toolpaths to measure parts with spindle probes. Share 3D reports with Autodesk Drive. (video: 2:07 min.)

5-axis programming

Efficient 3+2 programming

Machine complex features with fewer setups, shorter tools, and more aggressive feeds and speeds. (video: 2:10 min.)

5-axis machining

Machine the most challenging parts more safely and efficiently with continuous 5-axis machining. (video: 3:24 min.)

Expert 5-axis control

Make global or localized edits to 5-axis toolpaths for improved machine motion and shorter cycle times. (video: 2:50 min.)

Auto tool tilting

Simplify the process of creating collision-free 5-axis toolpaths with automatic tool axis tilting.

Interactive collision avoidance

Use interactive tools to help identify and repair toolpath motion that can cause collisions or near misses.

Automatic orientation vectors

Improve the synchronization between 5-axis simulations and actual NC program output.

Dynamic machine control

Select multiple regions of your toolpaths; use a virtual CNC machine to dynamically apply alternative tool axis settings.

Comprehensive tool support

Access tool types, including barrel cutters, and combine with 3- and 5-axis strategies to meet your machining needs.

Trusted NC code output

Output high-quality NC code for your machines. Access the latest machining functions on major NC controllers.

Specialized industry solutions

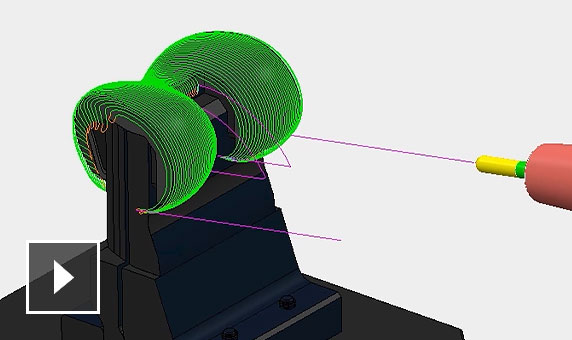

Industrial robots

Offline programming and simulation of robots. Analyze axis motion to reduce singularities and over-travel. (video: 2:56 min.)

Electrode manufacture

Automate the design, manufacture, inspection, and subsequent EDM burning of electrodes. (video: 2:47 min.)

Blisk and impeller machining

Use specialized 5-strategies to machine blisks, IBRs, and impellers with safe CNC machine motion. (video: 1:38 min.)

Blade milling

Get dedicated tools to safely machine turbine blades, vanes, and other airfoils with smooth 5-axis motion.

Port and manifold manufacture

Access specialized CNC machining strategies for the production of engine ports and manifolds.

Rib machining

Produce cutter-friendly toolpaths to mill ribs in molds and dies. Use as a low-cost alternative to EDM.

Simulation and verification

Stock simulation

Dynamic ViewMill provides improved image quality. New options to detect and display collisions with stock.

Stock analysis

Quickly identify material left unmachined using color-coded shading modes.

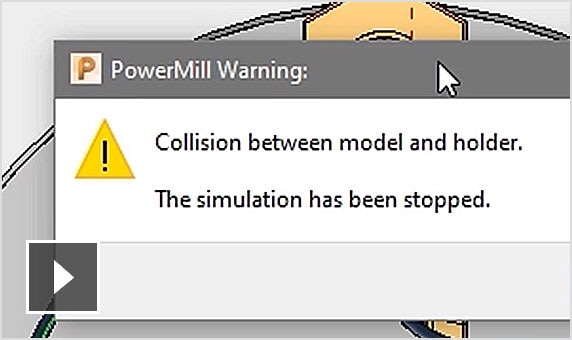

Automated verification

Use a single command to verify your CAM project to find and remove collisions and near misses.

Analyze machine motion

Simulate your toolpaths and NC programs using a virtual CNC machine. Highlight over-travel and rotary axis reversals.

Optimize machine motion

Dynamically orientate your virtual CNC machine tool to use shorter tools and more aggressive feeds and speeds.

Verification exports

Quickly transfer your NC programs and associated data to third-party verification software for added peace of mind.

More features

Autodesk Drive

Securely store, preview, and share PowerMill data with project stakeholders.

Ribbon interface

User-friendly interface shortens the learning curve, and offers customization for more experienced programmers.

Machining setups

Manage workplanes, stock, and clamps when programming parts using multiple operations.

2.5D programming

Interactively create 2D features, toolpaths, and NC code with control over cutter compensation.

Customization and automation

Embed your expertise into templates, macros, and toolbars. Minimize programming time and human error.

Tooling database

Build a searchable tool database and share across your engineering team for greater process control.

Shared views and setup sheets

Share vital information with your shop-floor operators. Minimize setup time and help avoid costly mistakes.

Every CAD support

Import surfaces, solids, or meshes from mainstream CAD systems. Create high-quality NC code regardless of model quality.

Follow Autodesk

Products

Buying

Support & learning

Autodesk

Autodesk is a leader in 3D design, engineering and entertainment software.

Please opt-in to receive reseller support

Autodesk releases PowerMill 2022 with enhanced finishing, new options for collision avoidance, and more

Article by Clinton Perry, PowerMill Product Marketing Manager

It’s that time of year again. The Autodesk PowerMill development team has just released the latest update to Autodesk’s CAM software. Following recent releases, this specific update includes a healthy mix of fixes, improvements, and new capabilities aimed at simplifying the daily life of CAM programmers around the world.

PowerMill 2022 – Customer Release: May 12, 2021

In this blog, we’ll provide a brief overview of the major highlights as well as offering links for those that want to learn more.

Finishing toolpaths now exclude flat areas

We’ll kick things off with a pretty neat improvement to some of PowerMill’s most commonly used finishing toolpaths (Steep & Shallow, Raster, and 3D Offset Finishing) to simplify the programming of parts containing flat/planar areas. PowerMill 2022 includes a new option to exclude flat areas during toolpath calculation. This small, but significant, update means programmers no longer need to spend time creating separate boundaries to limit the machining. Instead, PowerMill simply calculates a toolpath with the flat areas removed – simple!

But why is this such a big deal?

Well, it won’t surprise you to know that the vast majority of parts programmed with PowerMill consist of a mixture of doubly-curved surfaces, angled faces, and flat/planar regions. Generally speaking, the doubly-curved surfaces are best machined with spherical cutting tools (e.g. ball nose, tapered spherical, and so on) using a small stepover to achieve the desired surface finish. By comparison, the flat areas are best machined using flat-bottomed cutting tools (end mills, tip radiused end mills, and the like) with the tool axis aligned perpendicular to the flat face that’s being machined. This allows the use of larger stepovers that can produce an acceptable finish in less time than would be possible if a ball nose cutting tool was run with a smaller stepover. The ability to automatically split the model into steep, shallow and flat areas further simplifies the CAM programming of complex, feature-rich components.

From usage analysis, we know that these three finishing strategies are some of the most commonly used toolpaths inside PowerMill – and so this improvement should result in a lot of PowerMill users saving time and effort.

More accurate flat finishing

In our previous update, we discussed excluding flat areas from Steep & Shallow toolpaths – but these areas still need to be machined. In most cases, this is best achieved using a Flat Finishing toolpath (either Raster or 3D Offset). And it is here, where we see the next improvement in PowerMill 2022 – namely improved toolpath accuracy. In previous releases of PowerMill, there were occasions where the toolpath could contain chamfers in internal corners. These small errors could result in material being left un-machined which would need to be removed later – either using additional toolpaths or by manual polishing. This latest release of PowerMill now produces more accurate toolpaths – reducing the risk of material being left un-machined and helping to avoid the need for manual polishing.

As the underlying code is used in other areas of PowerMill, such as the previously mentioned Steep & Shallow, Raster, and 3D Offset finishing toolpaths, these and other features will also see improved accuracy.

Constant Z with Undercuts

Some releases ago, PowerMill’s Constant Z finishing toolpath type was updated to allow it to handle parts containing undercuts. In these cases, it was possible to machine the undercut either, a) using a lollipop or disk cutting tool (great if you only have a 3-axis machine tool), or b) by using PowerMill’s automatic 5-axis collision avoidance.

When using the automatic collision avoidance option, there were, unfortunately, rare occasions when a toolpath would be processed that was either incomplete or fragmented. This could result in additional toolpaths being required or even parts needing additional, manual polishing. With this latest release of PowerMill 2022, toolpath quality is greatly improved – as we can see if we compare the processing of this simple lug on an oil and gas part. In this case, the part is being machined with a Constant Z toolpath with “Spiral” switched on and the automatic collision avoidance activated. Note how, in previous releases, the toolpath suffers from excessive fragmentation, whereas the toolpath produced by PowerMill 2022 is complete – containing a single, smooth toolpath segment.

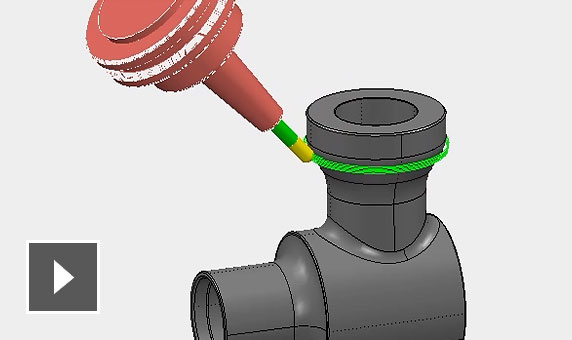

4-axis and Rotary with Automatic Collision Avoidance

Continuing the theme of automatic collision avoidance, this powerful option really has transformed 5-axis programming inside PowerMill. Customer feedback has been so positive that the development team decided to extend this same functionality to work with 4-axis and Rotary finishing toolpaths.

These toolpaths now include the option to define clearance values that will be used to tilt the 4th axis of the machine to avoid any collisions that might occur between the cutting tool assembly and the workpiece. In order to produce NC programs containing 4-axis motion only (for both cutting and non-cutting connection moves), it is also possible to define tool-axis limits that will constrain the toolpath. This ensures the resulting post-processed G-code file will only contain 4-axis commands – and not output any 5-axis movements that could cause the CNC machine tool any problems or trigger any alarms.

Projection Ranges

If you’ve ever used PowerMill’s various projection toolpath types, the chances are you’ve experienced this problem first hand. You’re trying to machine a particularly complex component and have decided to use Projection Finishing toolpath (either Curve Projection or Surface Projection) combined with a 3D surface that you produced using Autodesk Fusion 360 or Autodesk PowerShape. You’ve created a surface that will be used to control the shape and extent of machining – ensuring you cut the part exactly how you want. Unfortunately, when you calculate the toolpath, you see that it is machining up and onto the fixture that secures the part in place. Fortunately, you know that PowerMill can fix this by ignoring the fixture – so you simply re-calculate the toolpath – but this time remembering to tell PowerMill to ignore the fixture model. Great, that’s simple, right?

The image below shows a typical example of a component being machined with Surface Projection finishing. Here we can see the reference surface (shaded in cream) and the resulting projection toolpath over-machining the fixture.

Now imagine if the projection toolpath wasn’t just projecting onto the fixture, but was also projecting onto neighbouring parts of the model that you DO actually need to machine. You can’t just tell PowerMill to ignore that surface – as it needs to be machined! So how can you create the right toolpath?

This is where Projection Ranges can help. As the name suggests, these options allow you to define the distance that the projection toolpath is allowed to project away from the reference surface being used. A new option in the toolpath settings menu allows you to define both minimum and maximum projection range distances (for Curve and/or Surface Projection Finishing toolpaths). These will then be used to control the extents of the toolpath and prevent it from projecting onto neighbouring faces of the part (or the surrounding fixture).

While Projection Ranges were available in previous releases of PowerMill, they were only accessible using typed commands. The release of PowerMill 2022 sees these options being added to the toolpath settings form – making them even easier to find and use. The image below shows our previous example toolpath re-calculated with suitable projection range values. Note the over-machining has been removed.

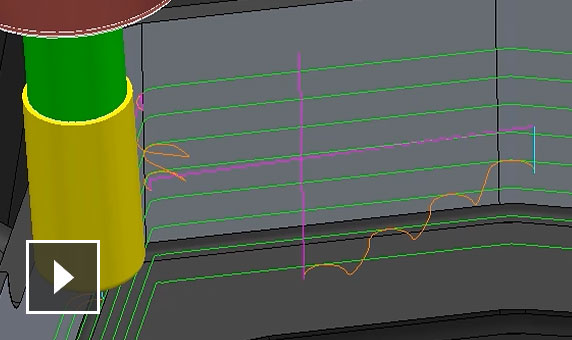

Staggered Start Points

The final major highlight we’ll include here relates to a new feature to allow start points on toolpaths to be staggered. This feature (which only applies to closed toolpath segments) automatically moves the start position of toolpath segments to improve machine motion, resulting in a better surface finish.

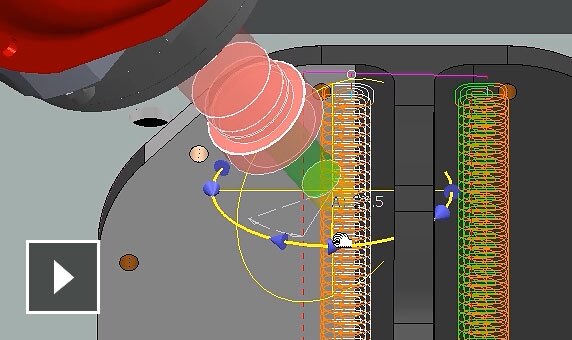

In this example, we’re using Swarf Finishing to machine the tapered sidewall of a part with the side of the cutting tool. Note that, by default, the toolpath start/end points are all aligned vertically (highlighted by the dotted red line). When this program is run on the machine the cutting tool will have to slow down at the end of one of the passes. It will then change direction to lead out of the material, move over to start the next lead-in move, before engaging into stock and continuing to machine the part. This movement is likely to leave a dwell mark on the component – partly due to the changing cutting forces but also the risk of one or more machine axes having to reverse direction.

It is possible to minimize the possible dwell mark by using arc lead in/out moves. However, by staggering the toolpath start points, it is possible to do an even better job. Staggering the points creates additional space between the end of one toolpath segment and the beginning of the next. This additional space helps maintain the forward motion of the machine tool, removing the need for the machine to reverse direction. This can have a positive impact on surface finish and machining cycle time – as the machine doesn’t have to slow down and speed up again.

If we apply staggered start points to our previous example, we can see a subtle but important change. The connection moves are staggered relative to each other (highlighted with a red line).

The use of staggered start points has an additional impact as each toolpath segment will, effectively, clean-up any witness line left by the preceding pass – further improving surface finish.

So that’s it. The top 6 improvements in PowerMill 2022. If you’d like to read about every fix and improvement, check out the official release notes at https://help.autodesk.com/view/PWRM/2022/ENU/

Want to learn more?

If you want to take a deeper dive into this release, why not watch this 30min release highlights.

Ready to download PowerMill 2022?

Existing customers

PowerMill 2022 will be released to customers starting May 12, 2021.

Eligible customers with an active subscription or maintenance agreement will be able to download the latest release starting May 12, 2021. Customers can download using the Autodesk Desktop App or by logging into their Autodesk Account. Alternatively, visit our Services Marketplace to contact your local Autodesk team and discuss your specific business needs.

Профессиональное программное обеспечение для высокоскоростной обработки, а также обработки на 5-осевом станке, предназначенное для промышленного производства

Обзор

Создание сложной 3D-геометрии для многоосевой высокоскоростной обработки на станках с ЧПУ

Возможности Fusion 360 и PowerMill (видеоролик: 1 мин 40 с)

Обзор PowerMill (видеоролик: 2 мин 4 с)

Производительность профессионального уровня при работе в PowerMill (видеоролик: 2 мин 48 с)

Эффективное программирование обработки по 3+2 осям (видеоролик: 2 мин 10 с)

Обработка на 5-осевом станке (видеоролик: 3 мин 24 с)

Гибридное производство (видеоролик: 2 мин 40 с)

АСУП Fusion 360 с PowerMillᴹᴰ предоставляет передовые стратегии программирования станков с ЧПУ для комплексного 3- и 5-осевого производства. Теперь есть доступ к Fusion 360 и дополнительным возможностям промышленного производства посредством расширений Fusion 360.

Решение сложных задач с помощью специализированных стратегий ЧПУ

Обработка изделий на станках с ЧПУ (видеоролик: 1 мин 32 с)

Получите доступ к обширной библиотеке стратегий PowerMill. Сократите время программирования благодаря быстрому расчету траекторий перемещения инструментов.

Эффективное использование станков с ЧПУ и высокое качество деталей благодаря PowerMill

Комплексная чистовая обработка с PowerMill (видеоролик: 3 мин 2 с)

Сколько стоит подписка на PowerMill?

Обратитесь к местному специалисту Autodesk по продажам, чтобы обсудить бизнес-потребности и расценки на подписку.

Существует ли бесплатная версия PowerMill?

Обратитесь к местному специалисту Autodesk по продажам, чтобы обсудить бизнес-потребности и узнать, какая ограниченная по времени версия PowerMill вам подойдет.

Какие версии PowerMill можно использовать после оформления подписки на текущую версию?

Подписка на PowerMill позволяет установить и использовать 3 предыдущие версии. Список доступных для скачивания файлов появится в вашей учетной записи на портале Autodesk Account по адресу autodesk.com после оформления подписки. См. также предыдущие версии, доступные подписчикам.

Можно ли установить PowerMill на несколько компьютеров?

Подписка на программное обеспечение PowerMill позволяет установить его не более чем на 3 компьютерах и других устройствах. Однако в каждый конкретный момент времени выполнить вход и использовать это программное обеспечение может только один определенный пользователь и только на одном компьютере. Дополнительные сведения см. в лицензионном договоре на программное обеспечение.

What’s new in PowerMill 2022

Fusion 360 with PowerMill® 2022 CAM software offers background verification of NC programmes and toolpaths, enhanced projection finishing, improved toolpath limiting, a faster interface and more.

Background verification

Save time by verifying NC programmes and toolpaths in a background process. (video: 1.46 min.)

Enhanced projection finishing

New range controls simplify the creation of plane, line and point projection finishing toolpaths. (video: 1.24 min.)

Quality of life improvements

New macro security, better toolpath limiting and a faster user interface. (video: 3.07 min.)

Finishing toolpaths exclude flats

Automatically exclude planar surfaces from certain finishing toolpaths so they can be machined separately. (video: 1.20 min.)

Flat machining

Improved flat area detection creates more accurate Raster and 3D Offset finishing toolpaths. (video: 1.30 min.)

Constant Z with undercuts

Simplify machining parts with undercuts by using Constant Z with improved collision avoidance. (video: 1.03 min.)

4-axis collision avoidance

Automatic collision avoidance can now be used with 4-axis and rotary toolpaths for increased safety. (video: 1:28 min.)

Projection ranges

Access advanced settings to control the extents of Surface and Curve Projection toolpaths. (video: 1.13 min.)

Staggered start points

Redistribute toolpath start points for smoother machine motion and improved surface finish. (video: 1.23 min.)

PowerMill 2021

Roughing collision avoidance

Automatic collision avoidance using 5-axis machine motion is now available for area clearance toolpaths. (video: 1:17 min.)

DMC for area clearance

Use dynamic machine control in PowerMill to edit the tool axis for localised regions of area clearance toolpaths. (video: 1:18 min.)

Faster collision drawing

The calculation and display of colliding toolpath sections is now multi-threaded and up to 68% faster. (video: 4.09 min.)

Speed improvements

Start machining parts sooner with faster toolpath calculations, shorter project opening times and more.

Faster model filleting

Model filleting respects active boundaries, resulting in up to 90% reduction in calculation times.

Additive updates

Improved strategies include faster profiling and a new alternating raster option for stronger parts.

Steep and Shallow ordering

Enhanced ‘top first’ ordering of toolpaths in PowerMill including steep and shallow produces safer, more reliable results.

Improved arc fitting

More accurate toolpath arc fitting improves machine motion, reduces cycle time and increases part quality.

Safer collision avoidance

Automatic tool axis updates using ‘edit within region’ now produces better quality results up to 98% faster.

Steep and Shallow enhancements

Improvements to steep and shallow finishing result in increased surface finish quality.

Smoother collision avoidance

Automatic collision avoidance now finds and avoids more issues, with safer, smoother 5-axis motion.

Safer Optimised Constant Z

Constant Z toolpaths produce better quality outcomes, including in cases where form tools are used.

Combined profile and raster DED

Combine profile and raster strategies in a single toolpath for better-quality additively manufactured parts.

PowerMill 2020

Speed enhancements

Reduce programming time with faster toolpath calculation, simulation and verification.

Faster leads and links

Leads and links calculations now use multi-threading for even faster processing times.

Uphill corner finishing

Machine steep corners with uphill cutting for more stable cut conditions and better surface finish.

More model export options

Export CAD models using a wider selection of file formats to improve collaboration across teams.

PowerMill Viewer

View, analyse and simulate project content on multiple computers at no additional cost.

Improved model filleting

Automatically add fillets to internal corners in finishing toolpaths to help minimise damaging tools.

Follow Autodesk

Products

Buying

Support & learning

Autodesk

Autodesk is a leader in 3D design, engineering and entertainment software.